DC Connect chooses Schleifenbauer as partner in a data center project in Iceland

About DC Connect

DC Connect specialises in the technical installation of 'white space' areas in data centres. It provides total solutions for clients for all of their data floor infrastructure needs, such as server racks, cabling, PDUs, connections, power and cooling. It is also experienced in the design of ‘meet-me rooms', spaces inside data centres where different companies can link together their individual network connections.

DC Connect is located in Hillegom (the Netherlands) and is active both domestically and abroad. Its focus is on commercial data centres (data centres that are involved in leasing server capacity to third parties) as well as organisations and institutions that have their own data centres, such as banks and insurance companies.

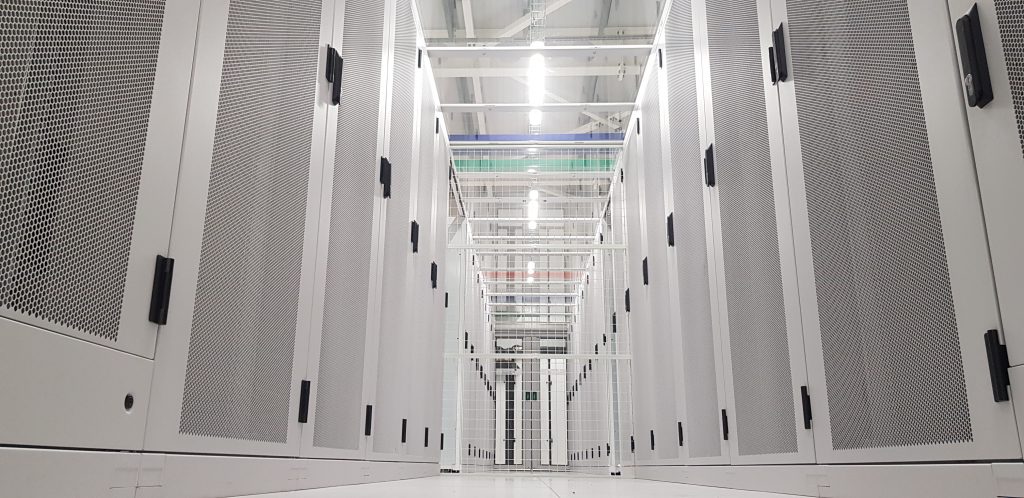

Launching a new data centre in Iceland

DC Connect was approached to equip the 'white space' for a new commercial data centre in Iceland, where it was responsible for realising a total solution for all of the data floor infrastructure requirements. A wonderful but nevertheless challenging task. On the one hand, there was a relatively short time frame available for completing the project, and on the other, there was the physical distance between the Netherlands and Iceland during preparations.

Exactly the right partners and suppliers were sought out for the project and a suitable solution was successfully achieved. A nice touch: The cable ducts for this project were specially designed in a variety of colours to help distinguish between the different rack cabling, routing and functions. The data centre was also equipped with intelligent Schleifenbauer PDUs and Siemens tap-off boxes, which were fitted with Schleifenbauer DPM3 energy meters.

Collaboration between DC Connect and Schleifenbauer

DC Connect made a deliberate choice for Schleifenbauer, particularly considering the power distribution and measurement aspects of this project. This meant that measurements were taken both inside and outside of the tap-off box, providing valuable information and data to both the data centre as well as customers of the server rooms. The PDUs were connected to A and B feeds, which was clearly indicated through the use of custom engraving on the PDU housing. And due to the modular structure of the Schleifenbauer PDU, a product could be assembled and delivered that satisfied all of the client's special requirements and requests.

Pieter van den Burg, Director at DC Connect: “We always select our partners, materials and components based on each specific project, under the motto, 'best for project, best for customer'. For example, we work together with several suppliers of PDUs and energy meters. For this specific project in Iceland, our client was already somewhat familiar with Schleifenbauer PDUs and energy meters, due to a reference project they had visited in the Netherlands. From DC Connect’s perspective, we also had a strong preference for working with Schleifenbauer in this project for a variety of reasons.

Firstly, this was because of the customised PDU configuration that was possible along with all of the benefits it offers the customer. Secondly, it had to do with how easy it was to monitor and configure multiple PDUs in one ring. And finally because of the compact DPM3-meter at only 2 DIN, which easily fits in the Siemens tap-off box used in this project. On top of that, we also felt confident in the collaboration and proper execution of the project thanks to all of our positive experiences with Schleifenbauer, including its reliability in meeting the deadlines set”.

Jos Janssen, head of sales & marketing at Schleifenbauer: “Of course, we are delighted to be involved in DC Connect’s incredible projects as a partner and PDU supplier. For this particular project, I visited Iceland on behalf of Schleifenbauer to discuss the requirements and requests for the data centre in terms of power distribution and measurements. We were able to clearly demonstrate our role as a specialist in the field of PDUs and energy measurement and make an active contribution to achieving satisfactory results. Ultimately, our solution was chosen, which we were then able to successfully implement within the set parameters and deadlines. We are not only proud of this project, but also of our collaboration with DC Connect.

More information

For more information on DC Connect, please visit their website at: https://www.dcconnect.nl.

Would you like more information about this collaboration, or are you interested in Schleifenbauer's products and services in energy measurement and power distribution? Please have a look at our website or contact our sales team via info@schleifenbauer.eu.

This article has been written in collaboration with:

![]()

.

Download this customer case as a PDF-document:

Impression of the project: